首页 » 质量管理系统

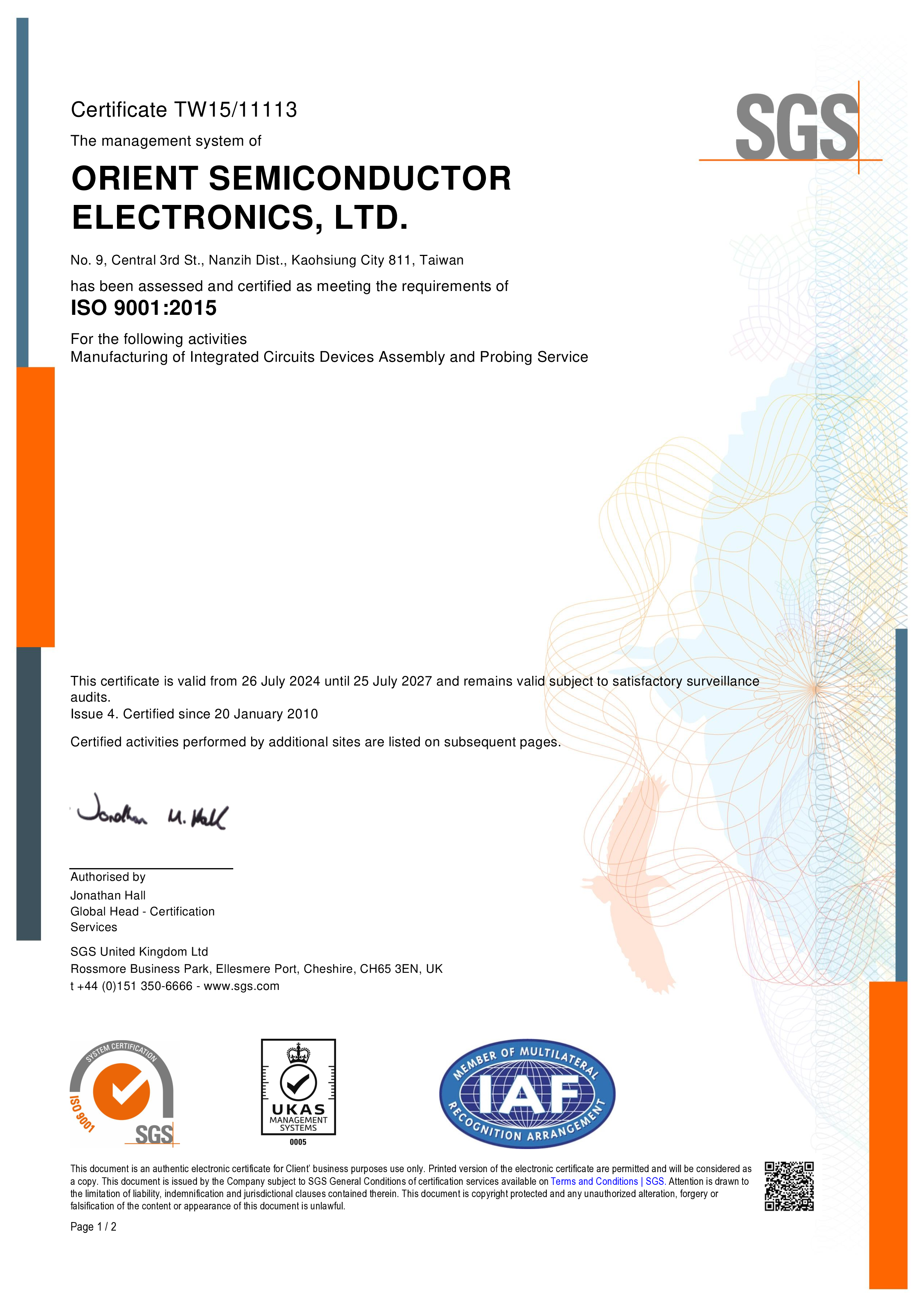

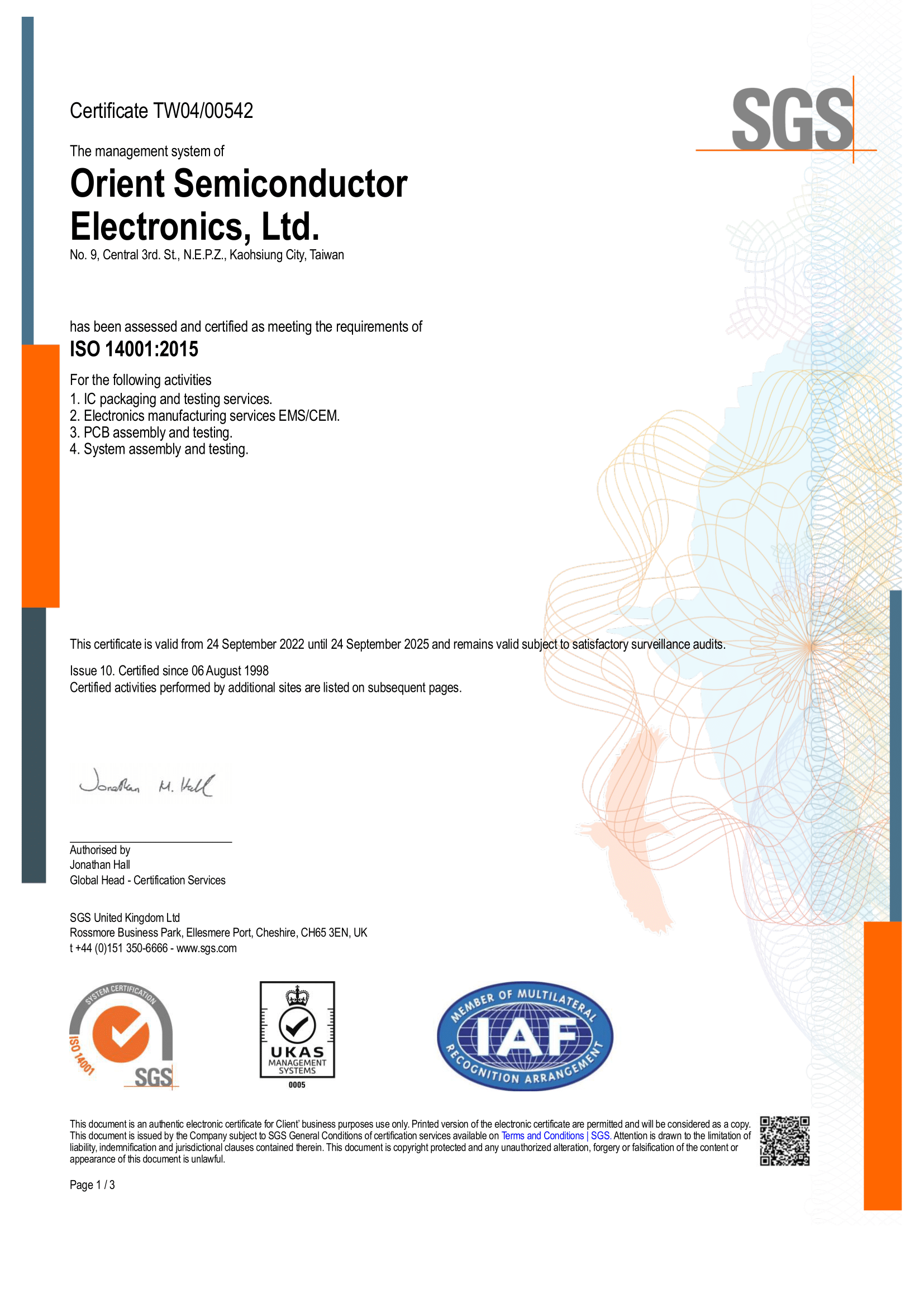

国际认证

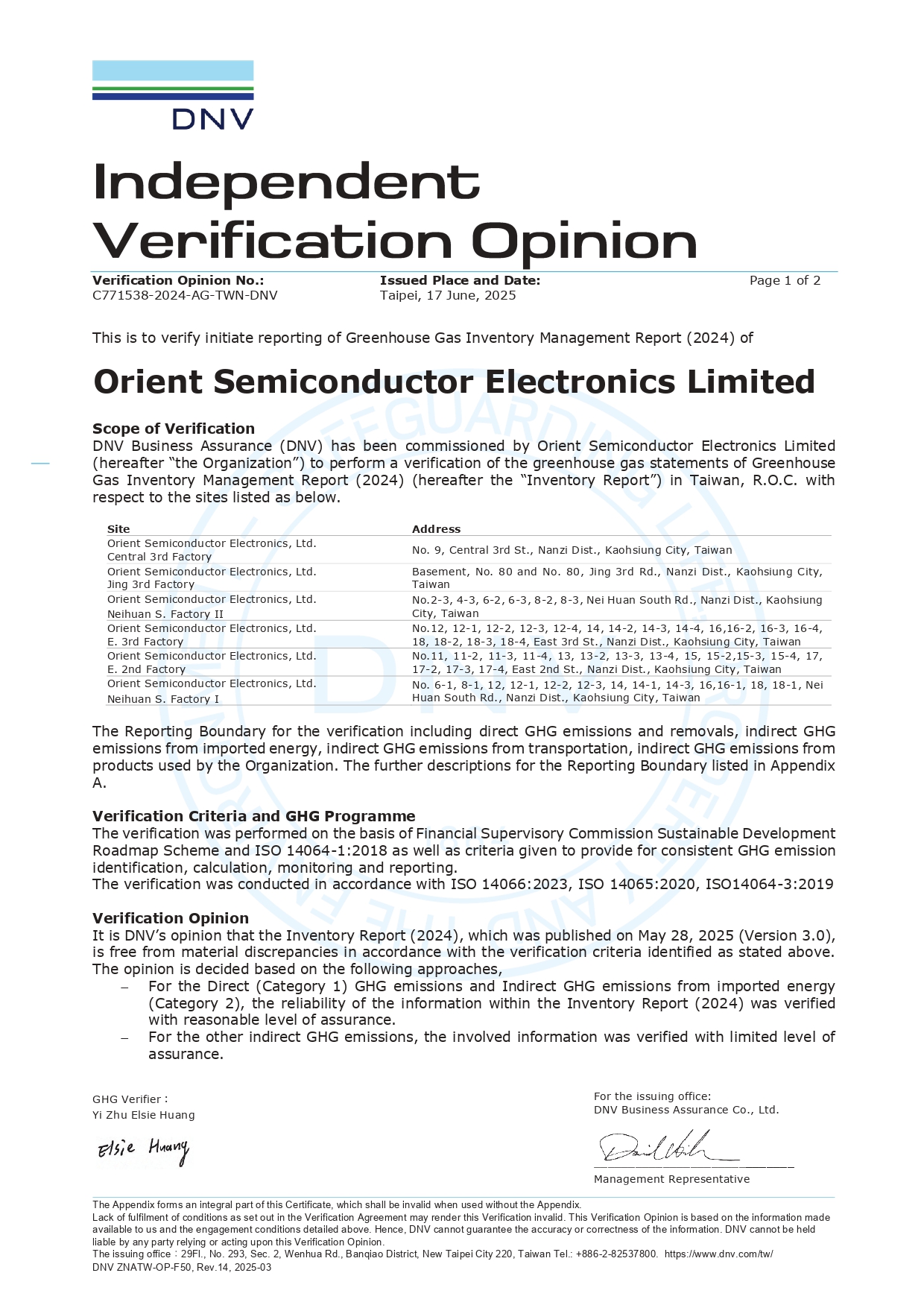

透过取得各项的认证来达成我们对质量的承诺,我们不仅仅是导入这些国际标准,而且要持续改善整体质量管理系统的有效性。亦符合TAA贸易协议法规范。

封装测试服务

电子制造服务

环境与职业安全卫生管理

*备注:认证厂域与认证效期详各证书所揭示

资讯安全

品质管理

失败分析实验室

华泰电子拥有先进的仪器与实验设备,有能力依厂内及客户的回馈进行相关性的失败分析(Failure Analysis, FA ) ,进行持续性的品质改善。

需求

客户回馈/内部需求

非破坏性分析

■Curve Tracer

■SAM

■X-Ray

■SEM&EDX

■Digital Microscope

■High/Low optical Microscope

破坏性分析

■Grinding/Polishing Machine

■Precison sectioning Saw

■Probe Station

■Laser Decap

■Ion Milling

报告

分析报告

非破坏性分析

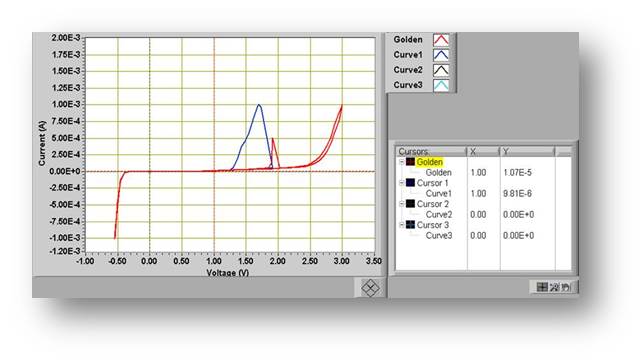

Curve Tracer

KEITHLEY 2636B

Capability

1fA/1mV

Application

Curve tracer is a electronic test equipment used to analyze the characteristics of semiconductor devices.

X-ray

SEC X-eye SF-160

Capability

Real time observation

Application

X-ray is used for illustrate the internal structure through x-ray.

SAM (Scanning Acoustic Microscope)

Sonoscan D9650

Capability

Transducer frequency:

15MHz/30MHz/50MHz/100MHz

Application

SAM is used to examine, measure and photograph the IC structure with supersonic waves.

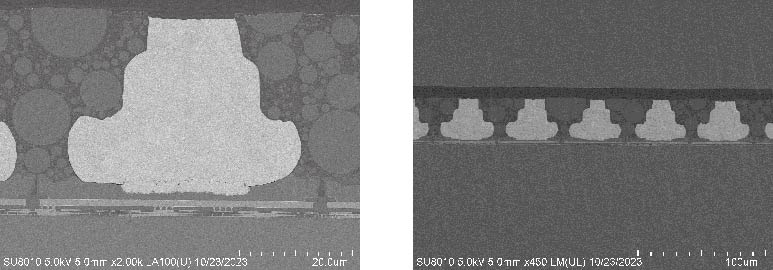

SEM (Scanning Electron Microscope) & EDS (Energy Dispersive Spectrograph)

Hitachi SU8010(SEM)

HORIBA X-max(EDS)

Capability

A/V.:0.5KV~30KV,

Magnification: 10X~100000X / Z:5~92

Detector area:50mm²

Application

SEM is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons.

EDS is an analytical technique used for the elemental analysis or chemical characterization of a sample.

Digital Microscope

KEYENCE VHX-7000 / EA300

Capability

Real Zoom Lens: 20X~4000X / Z: 1~92

Application

Digital microscope is an optical microscope that uses optics and a digital camera to magnify the sample with 3D contrast (DOF) to output to the monitor .

High/Low Power Optical Microscope

Nikon LV150

Capability

Eyepiece: 10X

Objective Lens:

2.5X/10X/20X/50X/100X

Application

High/Low Power Optical Microscope is a type of microscope to use visible light and a system of lenses to magnify the preliminary inspection of sample surface structure.

破坏性分析

Grinding/Polishing Machine

Struers Tegramin-20

Capability

Variable platen speed:

40~600 rpm

Application

The Grinding and Polishing machine is the tool used to grind/polish the sample near-by the suspected point for further investigations.

Precision Sectioning Saw

Allied 20-1000

Capability

Various Blade Type, Max Speed:4000 rpm

Application

Precision Sectioning Saw is the machine tools used for cutting the sample before grinding.

Laser Decap

Con Semi FAT cat II

Capability

I.R. Laser: 20 watt

Application

Laser Decap is the process of removing the protective cover of a microchip so that the contained die is revealed for visual inspection of the micro circuitry imprinted on the die.

Ion Milling

Hitachi IM4000

Capability

A/ V : 0 to 6 kV

Milling rate (max.) : (Materials Si)

For X-section milling: 300μm/hour

For Flat milling: 2~20μm/hour

Application

Ion milling machine thins the sample until it is transparent to electrons by firing ions at the surface from an angle and sputtering material from the surface.

Probe Station

MM 6000

Capability

4 Manipulator

Application

Probe station is used to physically acquire signals from the internal nodes of a semiconductor device.

Failure Analysis Equipment

| S/N | Equipment | Manufacturer | Model | Set | Capability |

| 1 | High/Low Power Optical Microscope | Nikon | LV 150 | 1 |

Eyepiece:10X, Objective Lens:2.5X/10X/20X/50X/100X |

| LV 150N | 1 | ||||

| 2 | Digital Microscope | KEYENCE | VHX-7000 / EA300 | 1 | Real Zoom Lens: 20~2000X / Z: 1~92 |

| VHX-7000 | 1 | Real Zoom Lens: 20~4000X | |||

| 3 | X-ray | SEC | X-eye SF-160 | 1 | Real time observation |

| YXLON | Y.CHEETAH | 1 | |||

| COUGAR | 2 | ||||

| Y.COUGAR SMT | 4 | ||||

| 4 | SAM (Scanning Acoustic Microscope) | SonoScan | D9650 | 1 | Transducer frequency: 15MHz/ 30MHz/50MHz/ 100MHz |

| 5 | Curve Tracer | KEITHLEY | 2636B | 2 | Resolution: 1fA/1mV |

| 6 | Laser Decap | Con Semi | FAT cat II | 1 | I.R. Laser: 20 watt |

| 7 | SEM (Scanning Electron Microscope) | Hitachi | S-3500N | 1 | A/V.:5KV~20KV, Magnification: 10X~100000X |

| SU8010 | 1 | A/V.:0.5KV~30KV, Magnification: 10X~100000X / Z:5~92 |

|||

| 8 | EDS (Energy Dispersive Spectrograph) | HORIBA | X-max | 1 | Detector area:50mm² |

| 9 | Probe Station | MM | 6000 | 1 | 4 Manipulator |

| 10 | Cross Section Machine | Struers | Tegramin-20 | 1 | Variable platen speed: 40~600 rpm |

| 11 | Ion Milling | Hitachi | IM4000 | 1 |

A/ V : 0 to 6 kV Milling rate (max.) : (Materials Si) For X-section milling: 300μm/hour For Flat milling: 2~20μm/hour |

| 12 | Precision Sectioning Saw | Allied | 20-1000 | 1 | Various Blade Type, Max Speend:4000 rpm |

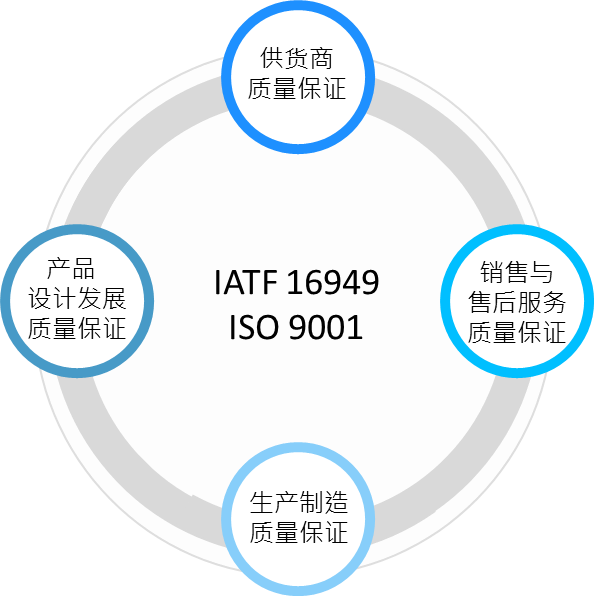

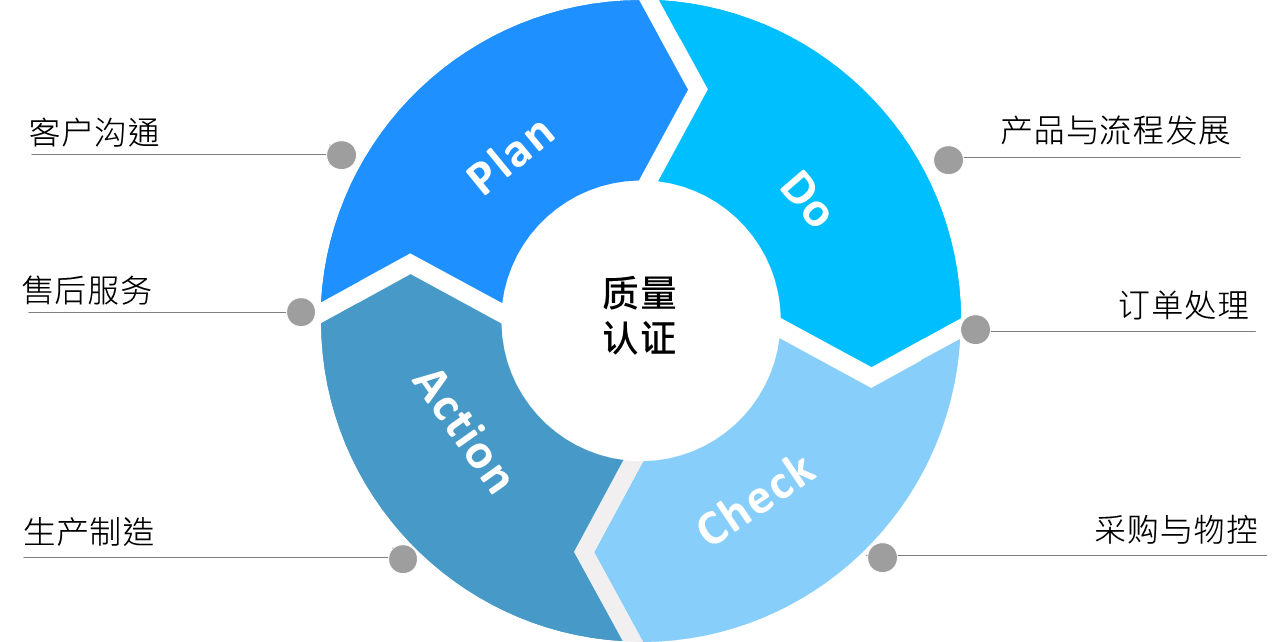

华泰电子依据IATF 16949以及ISO 9001建立品质管理系统体系,发展以客户为导向的管理流程,善用多项品质管理工具,持续衡量与监控各项流程的效率与有效性,来满足客户需求与期待,以提升竞争的优势。

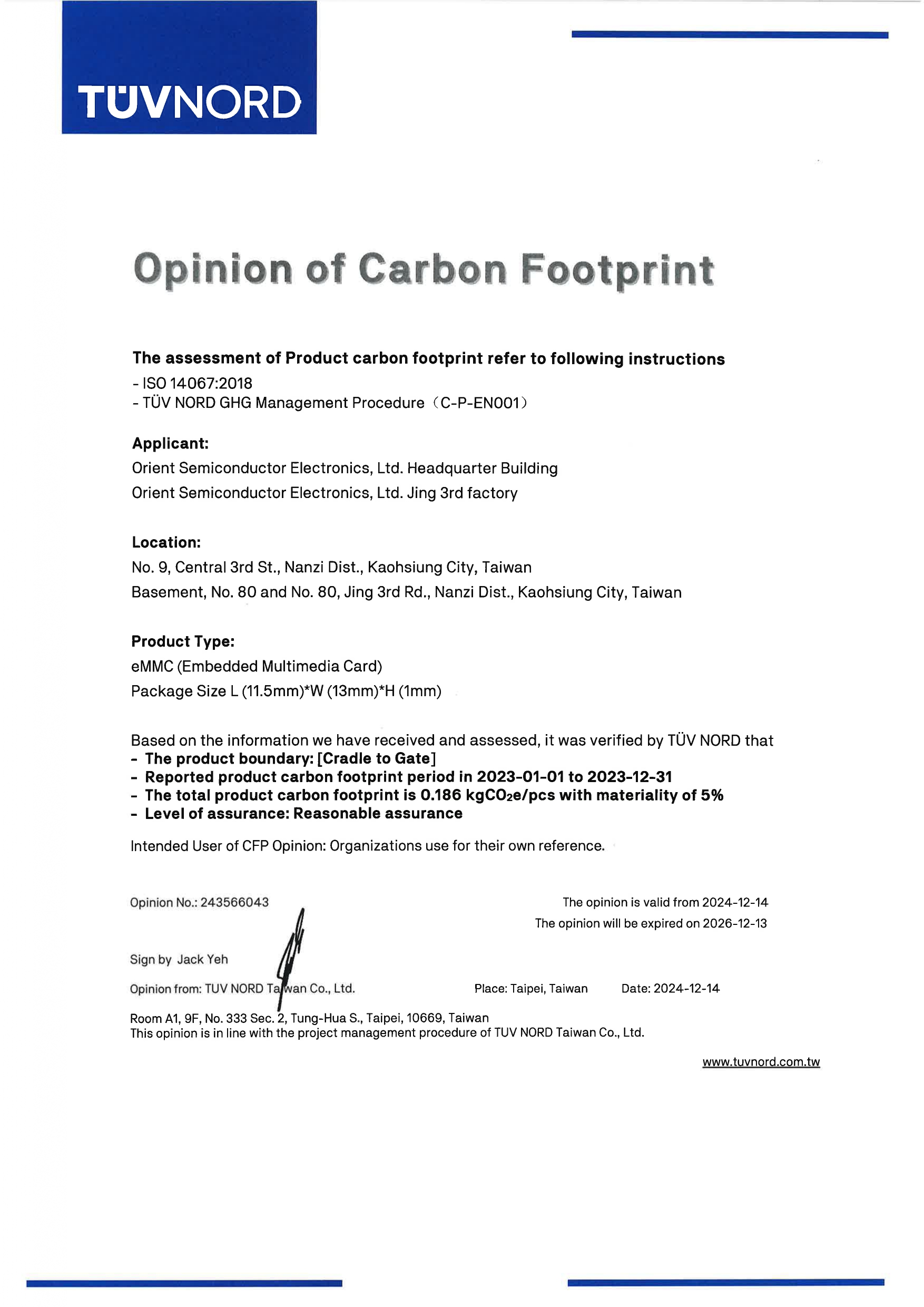

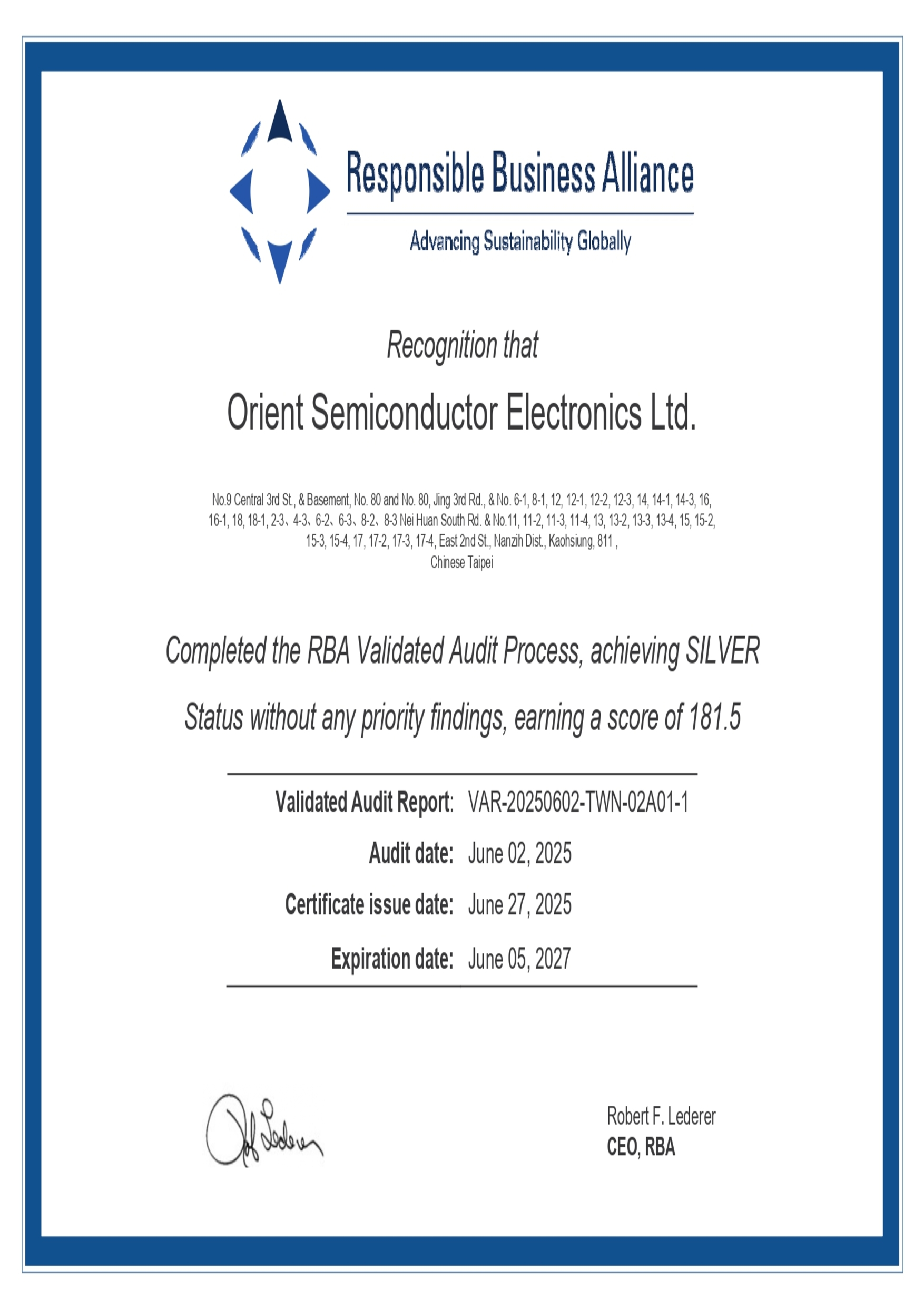

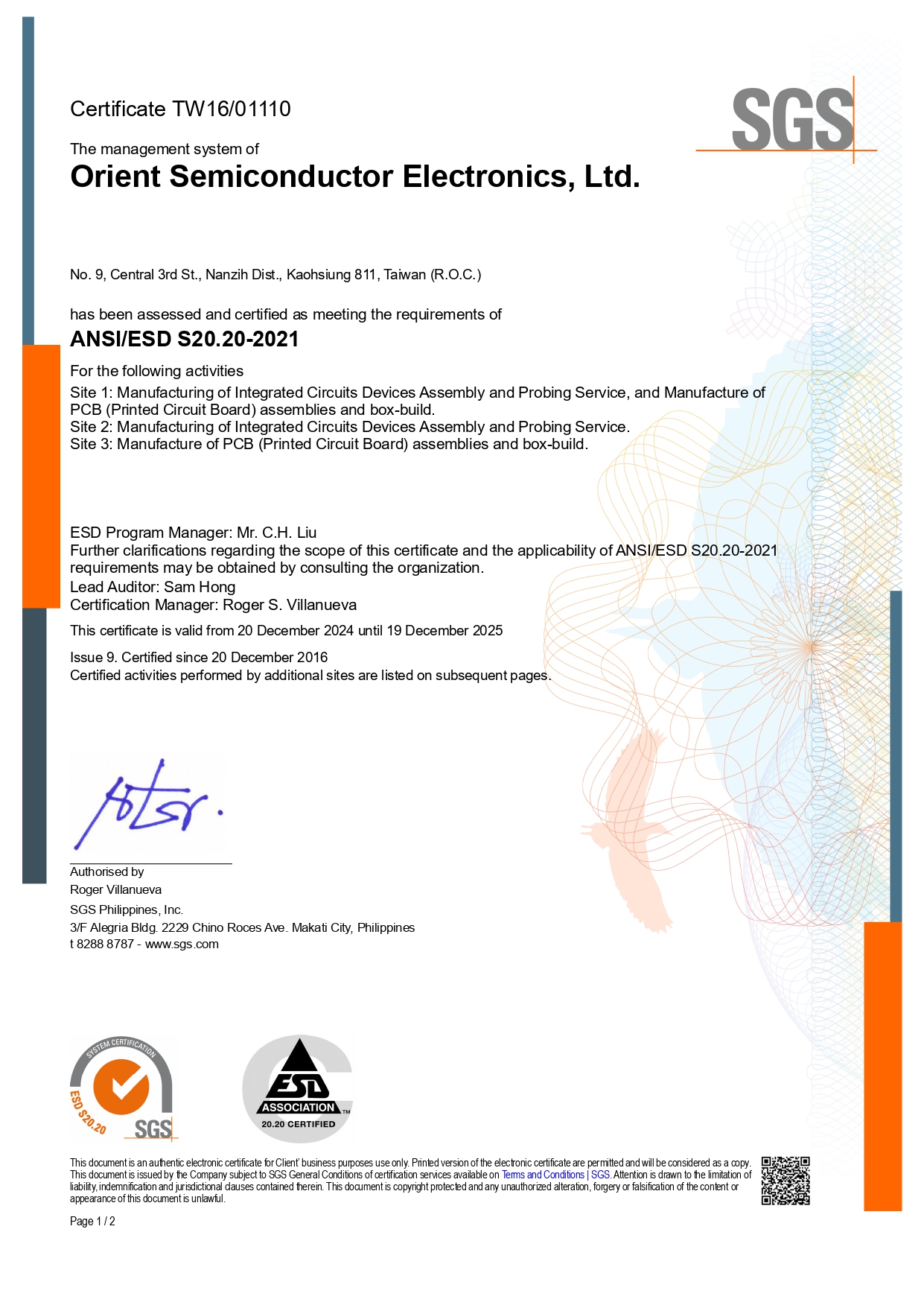

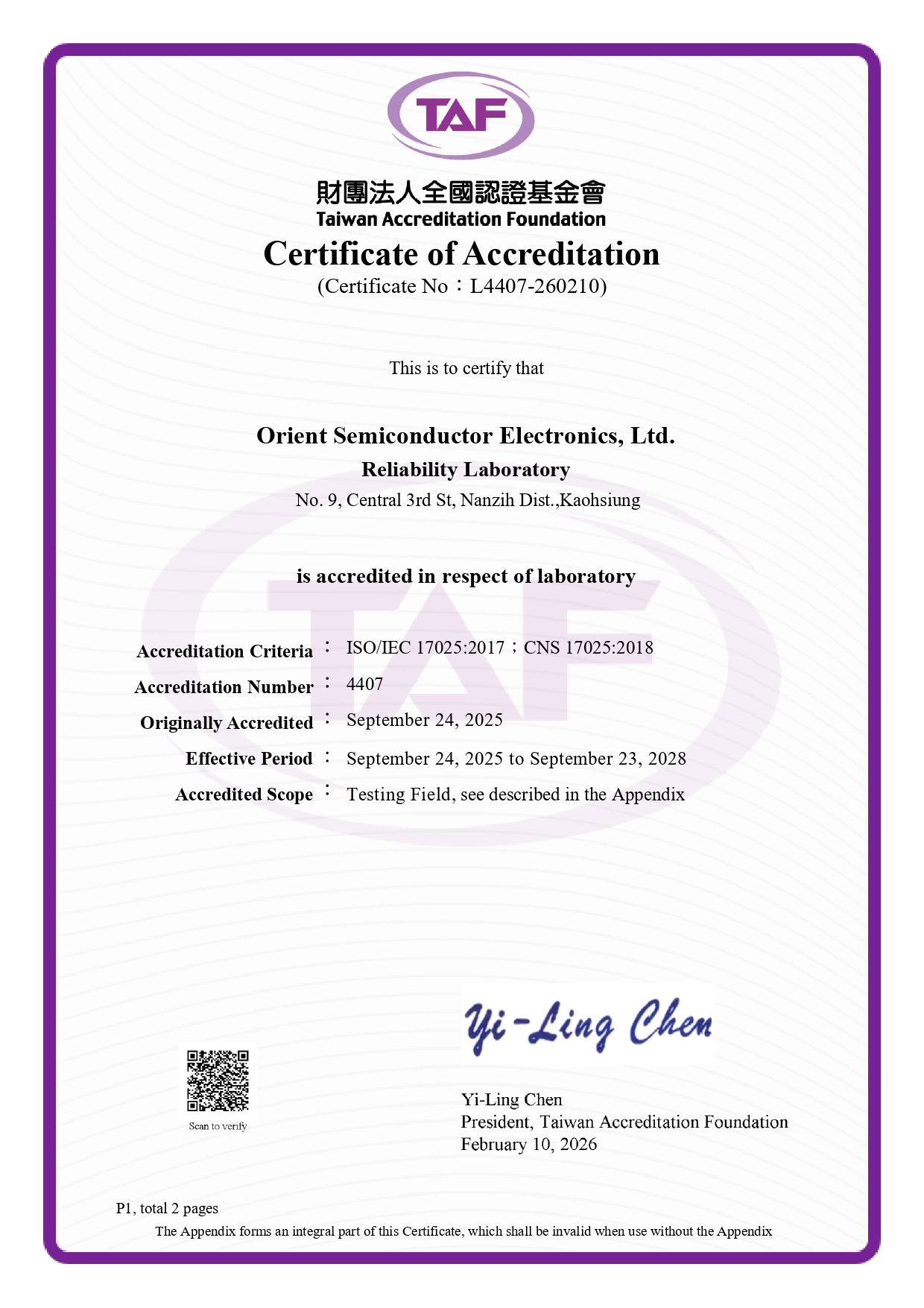

.png)

.png)

1_page-0001.jpg)

_公告版_page-0001.jpg)

1_page-0001.jpg)