Home » Quality Management System

Quality Policy

To satisfy our customers’ targets through optimization of process capability and continuous improvement throughout our organization.

OSE is a customer-oriented company developing multi management systems. Our quality and service are admirable for customers. Many significant customers become good partners with OSE in business. OSE is a historic and international semiconductor assembling and testing company.Our commitment in product delivery is capable to meet customers’ requirements and strict implementation in quality control. For customers, we firmly persist in performing satisfactory continual improvement.

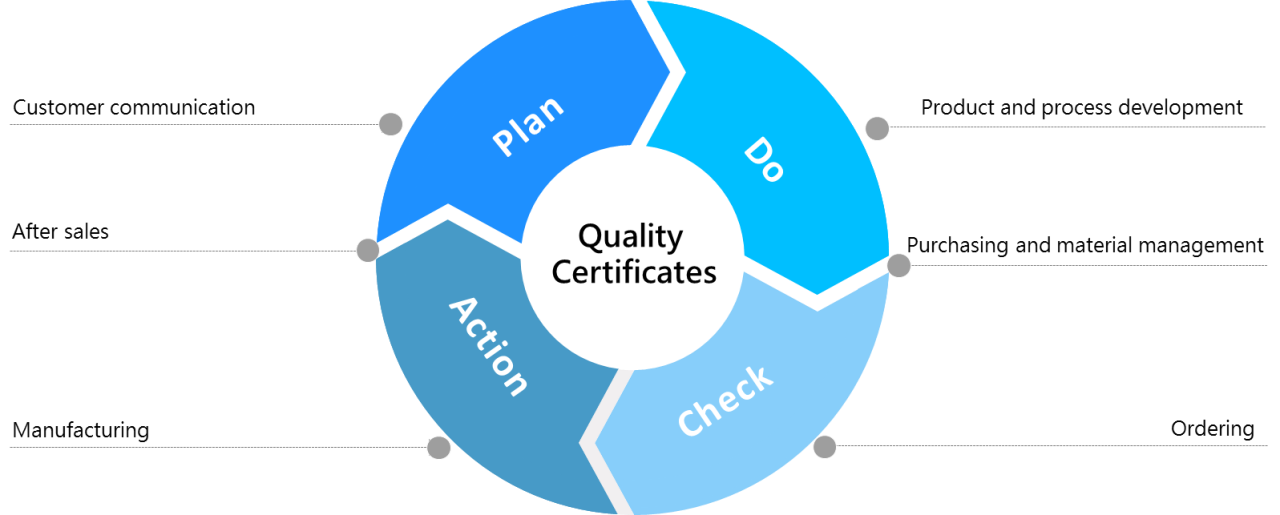

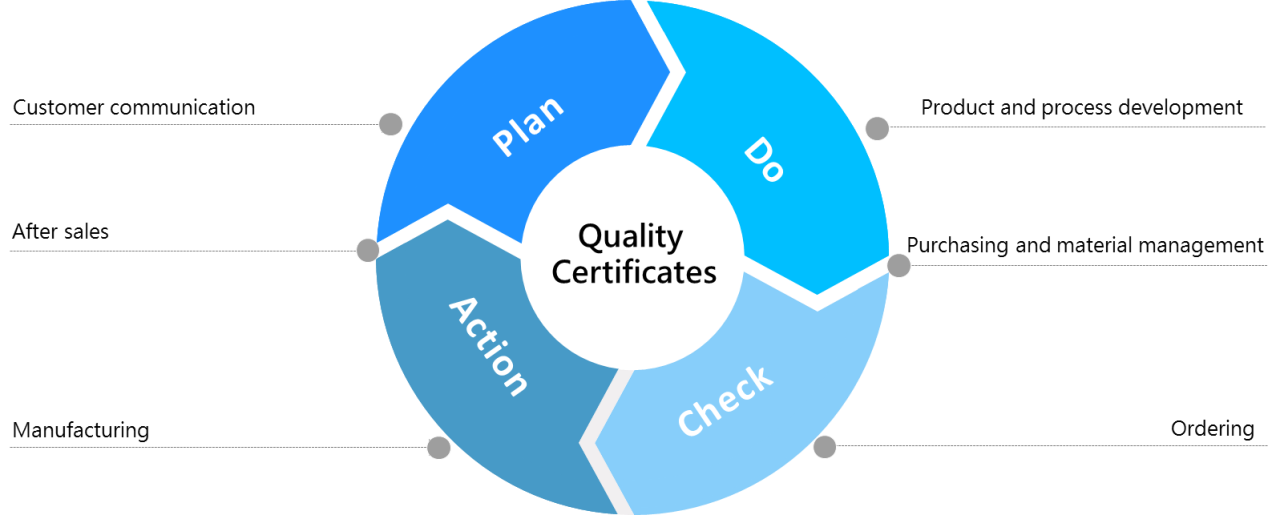

Quality Management System

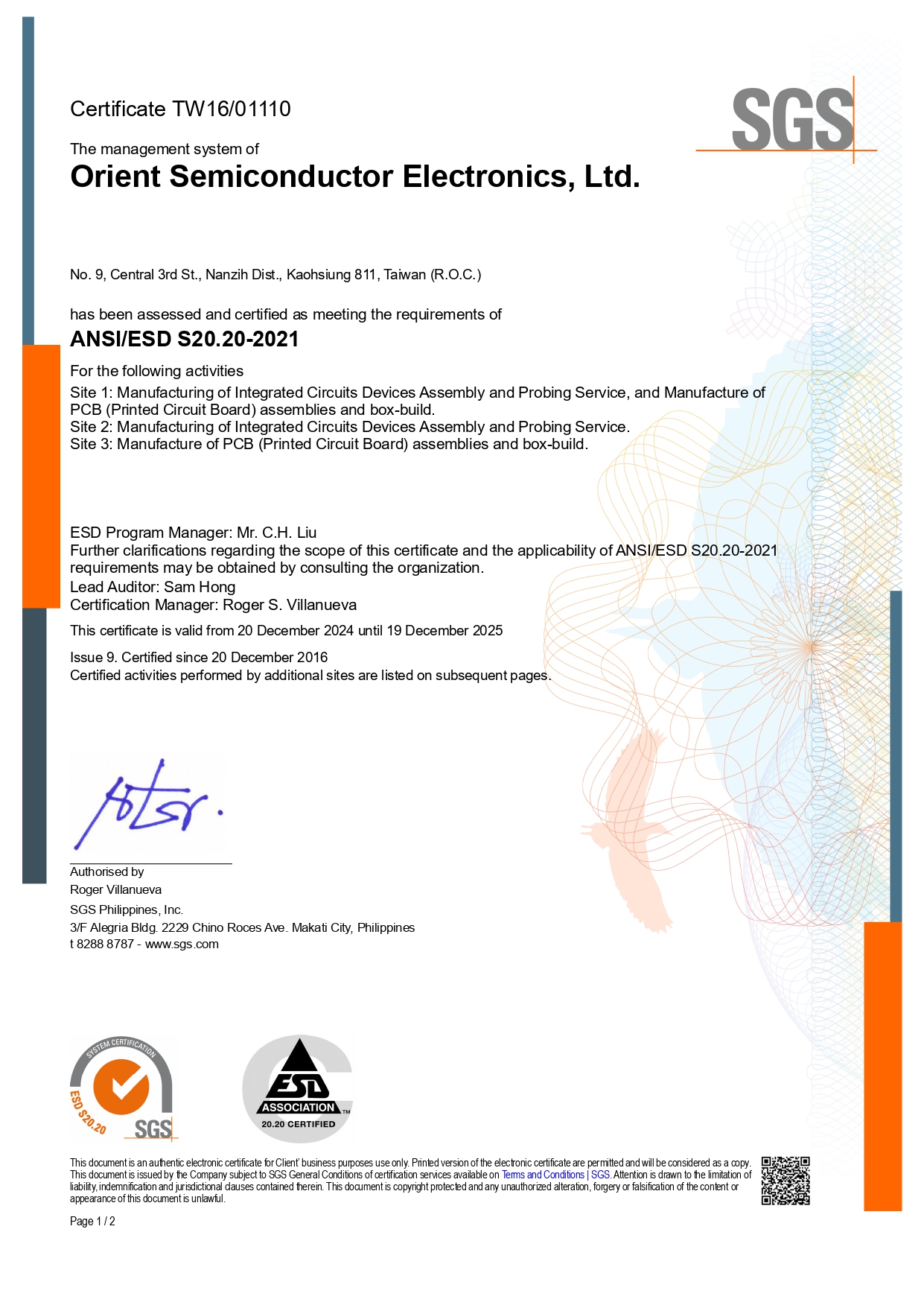

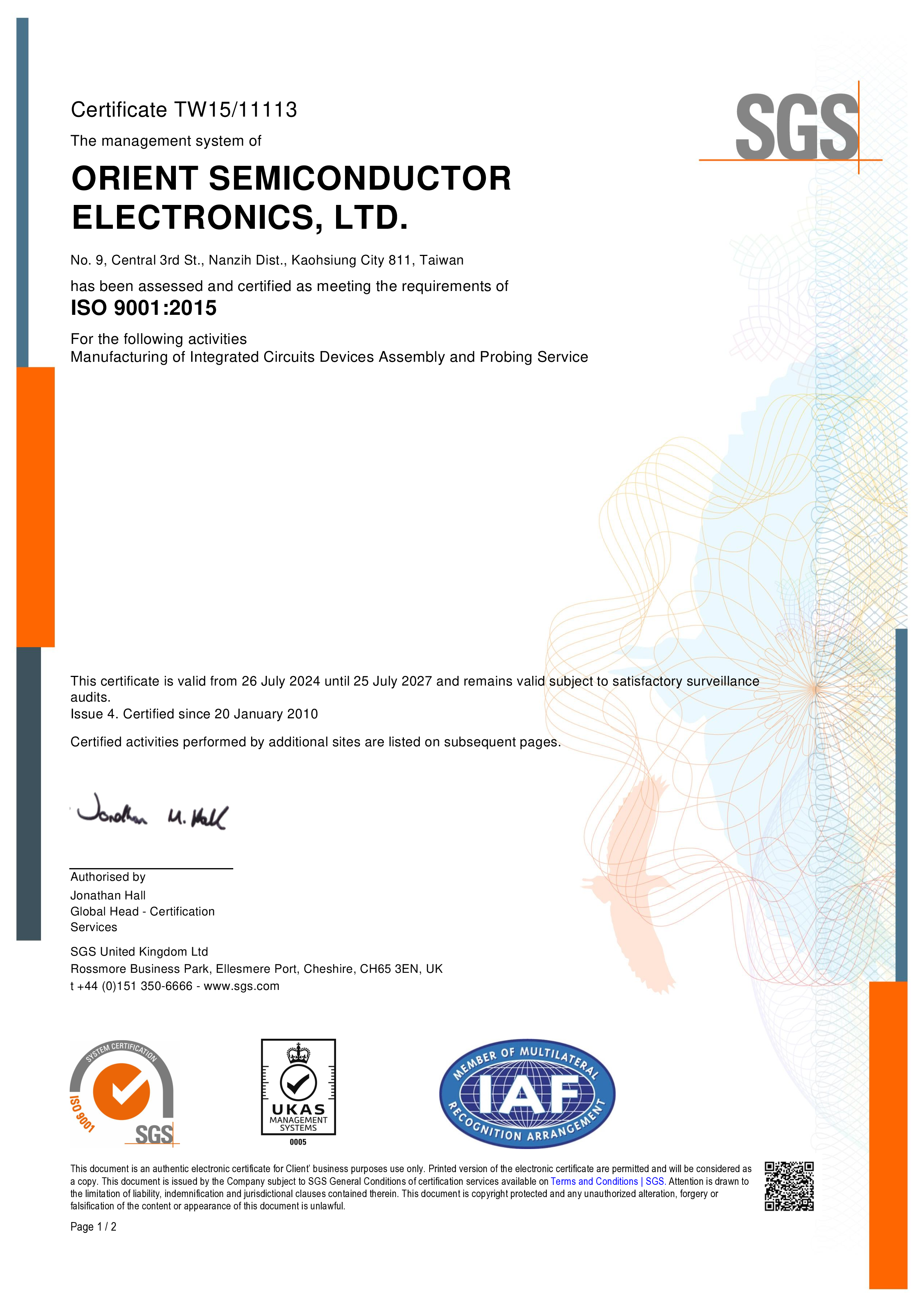

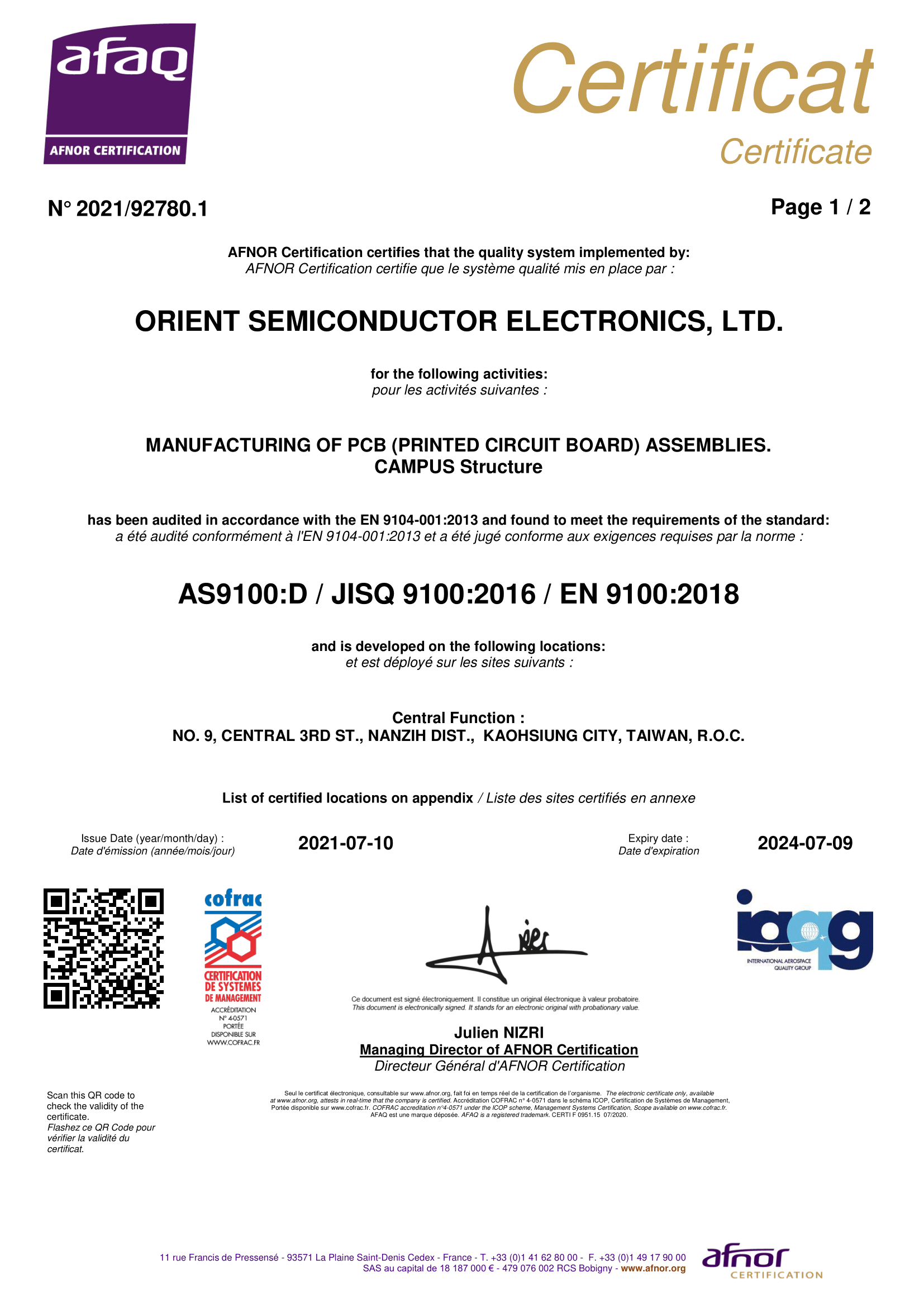

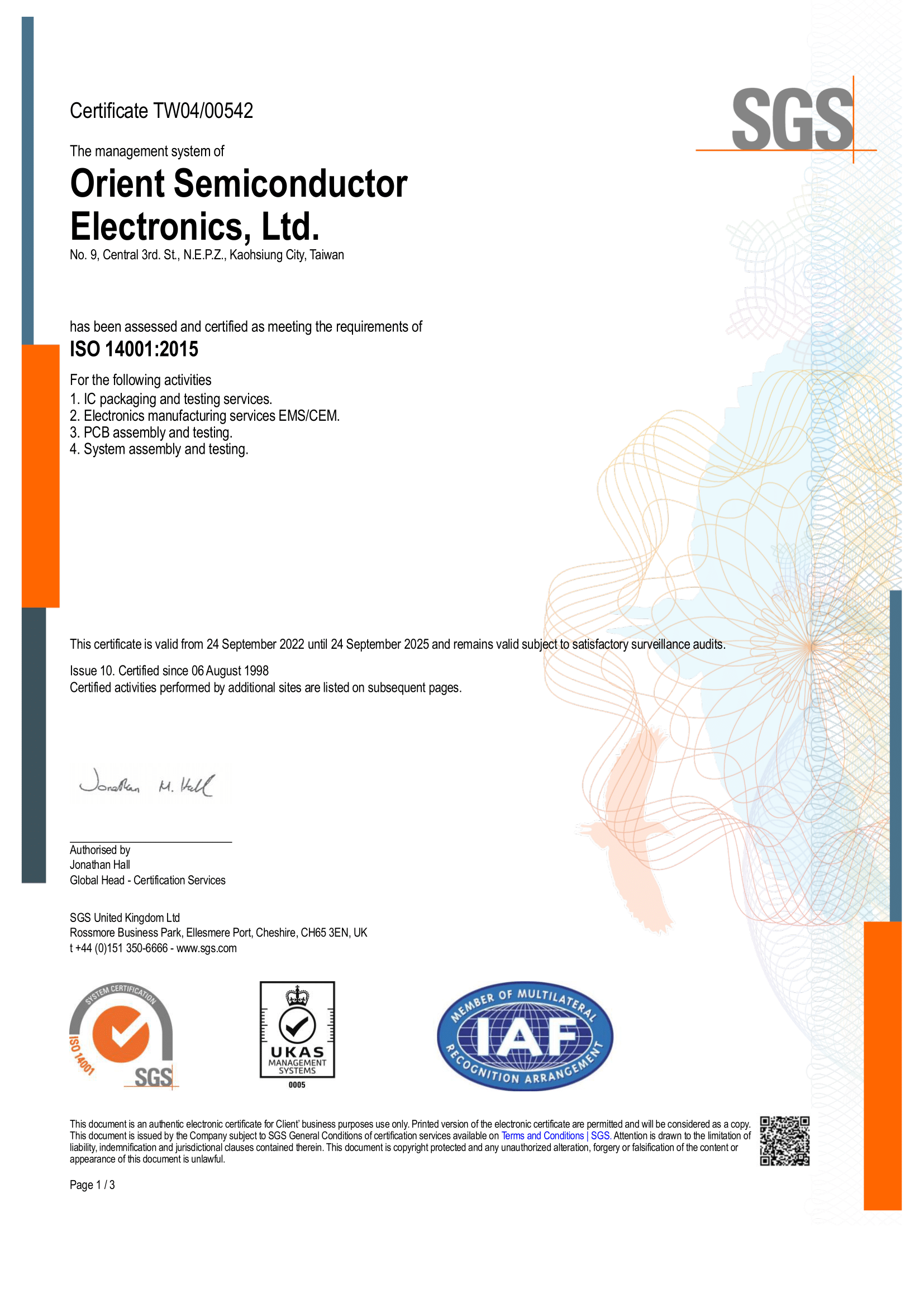

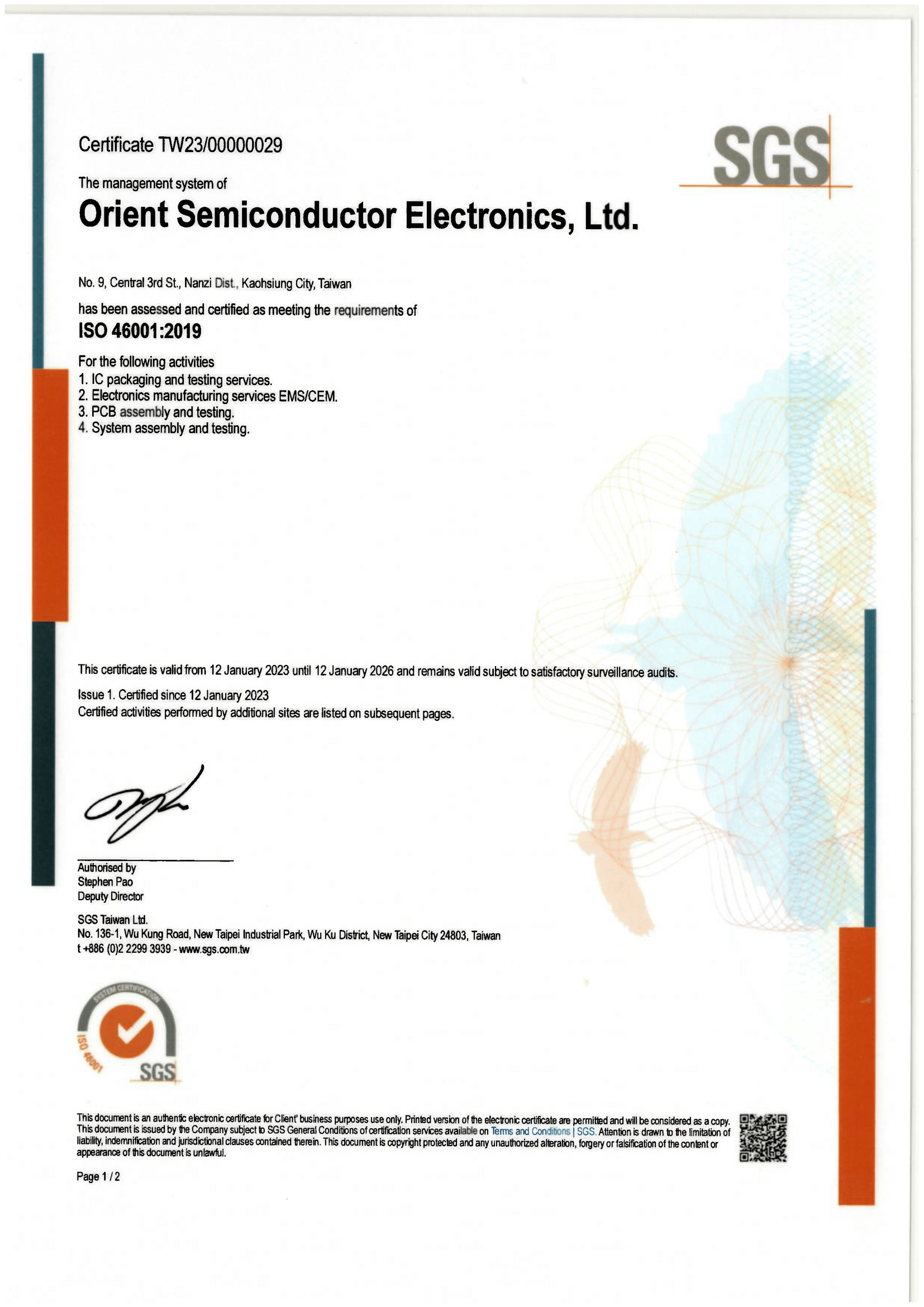

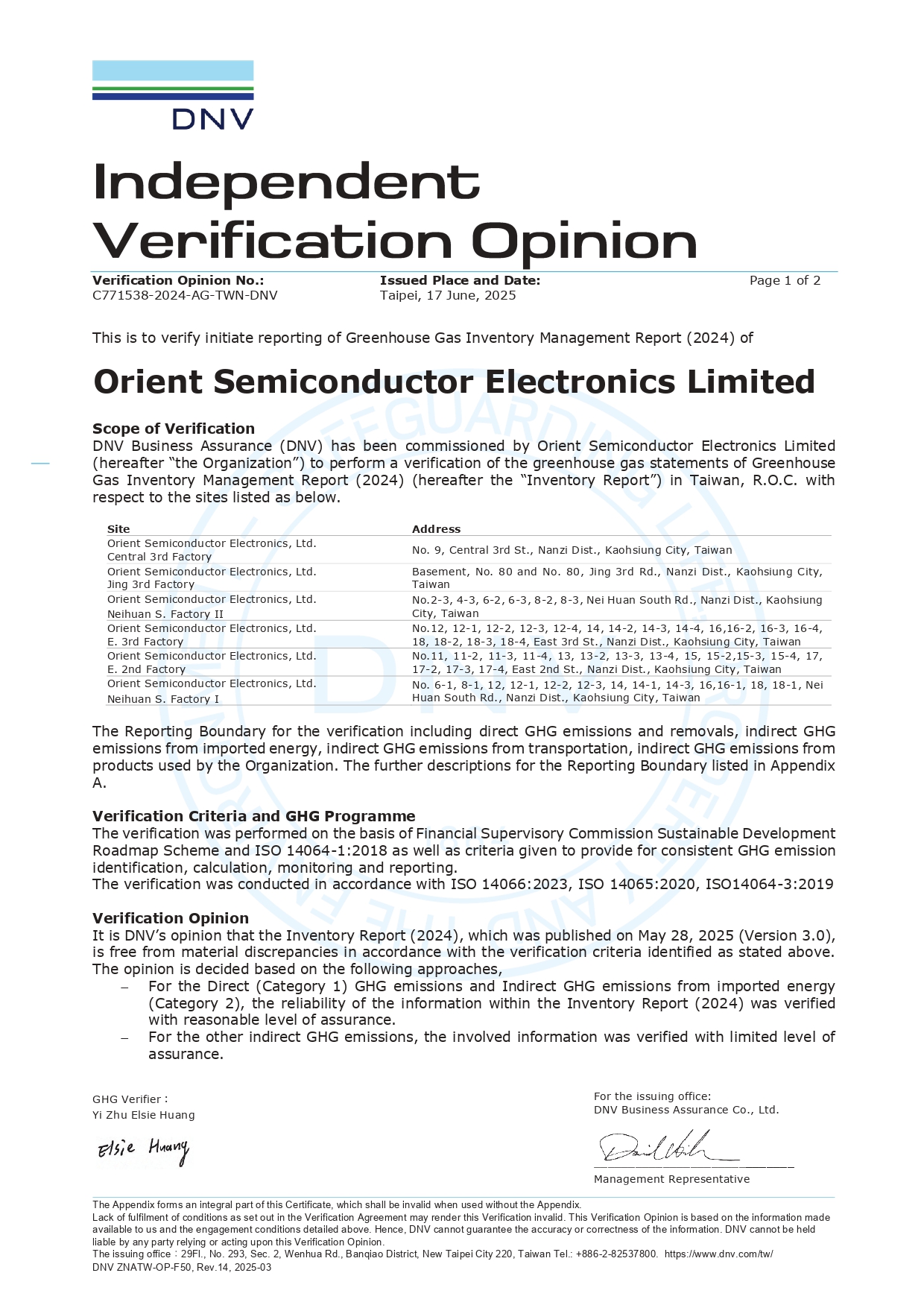

OSE established a quality management system according IATF 16949 and ISO 9001 including six customer-oriented processes: customer communication process, product and process development process, purchasing and material management process, ordering process, manufacturing process and after sales process. We define key performance indicators(KPI) for each process to continually assess and monitor it effectiveness and efficiency. Also, OSE is assessed and verified as meeting of requirements of IATF 16949, ISO 9001, ISO 13485、AS9100、ISO 14001, ISO 45001 CNS 45001、ISO 5001、ISO 46001、ISO 14064、ISO/IEC 27001、IECQ QC080000 and ANSI/ESD S20.20.

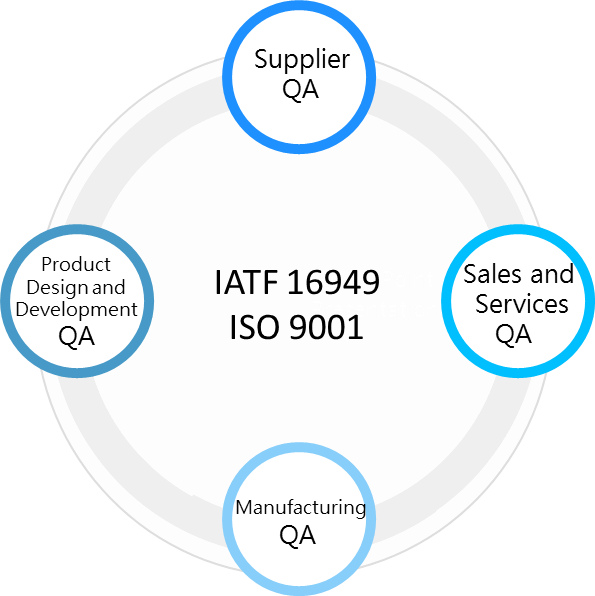

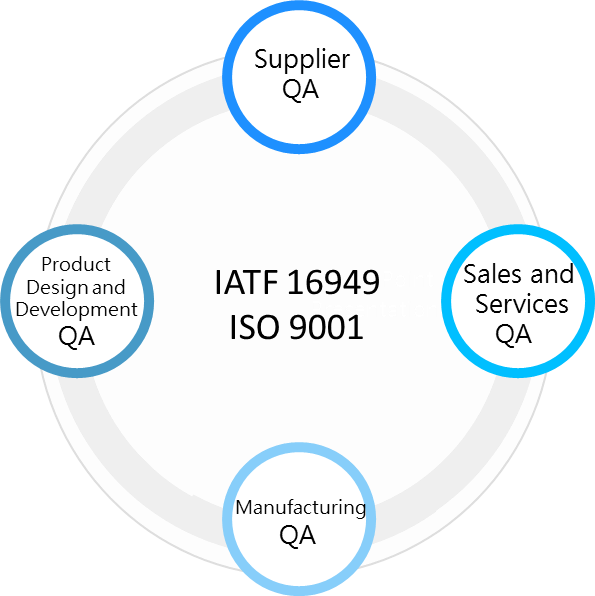

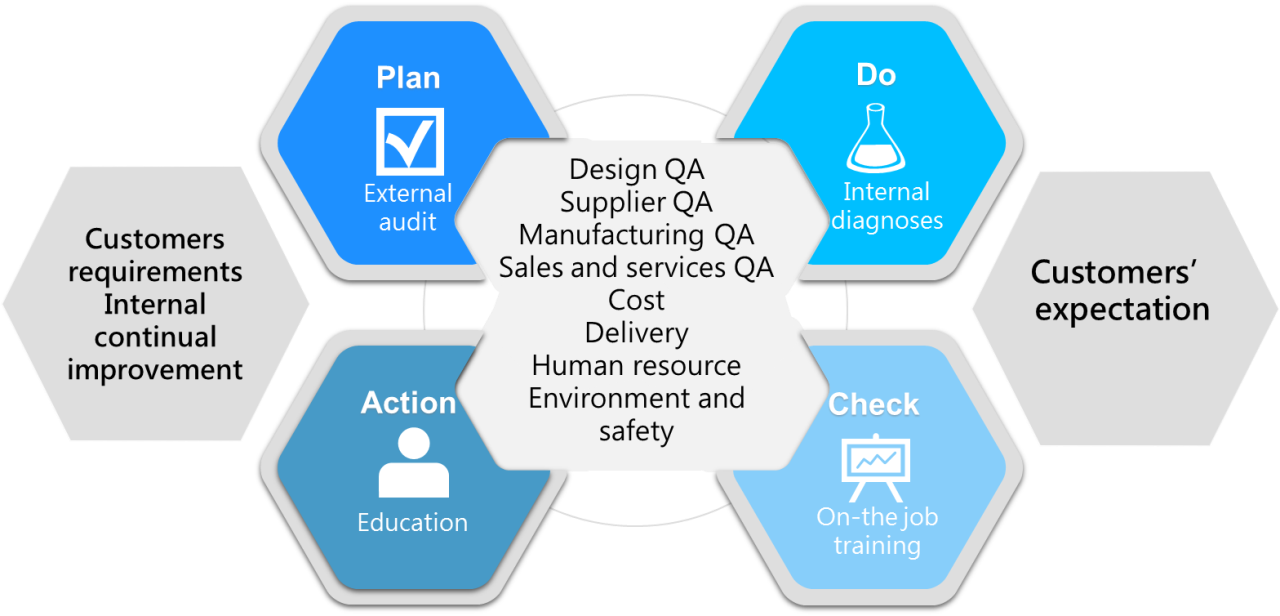

Total Quality Management

OSE develops total quality management aiming at design QA, supplier QA, manufacturing QA and sales and services QA, also at cost, delivery, human resource and environment and safety.

OSE continually converts customers’ requirements and internal needs into customer expectation and standardization by external audit and internal diagnoses and supporting by education and on-the job training.

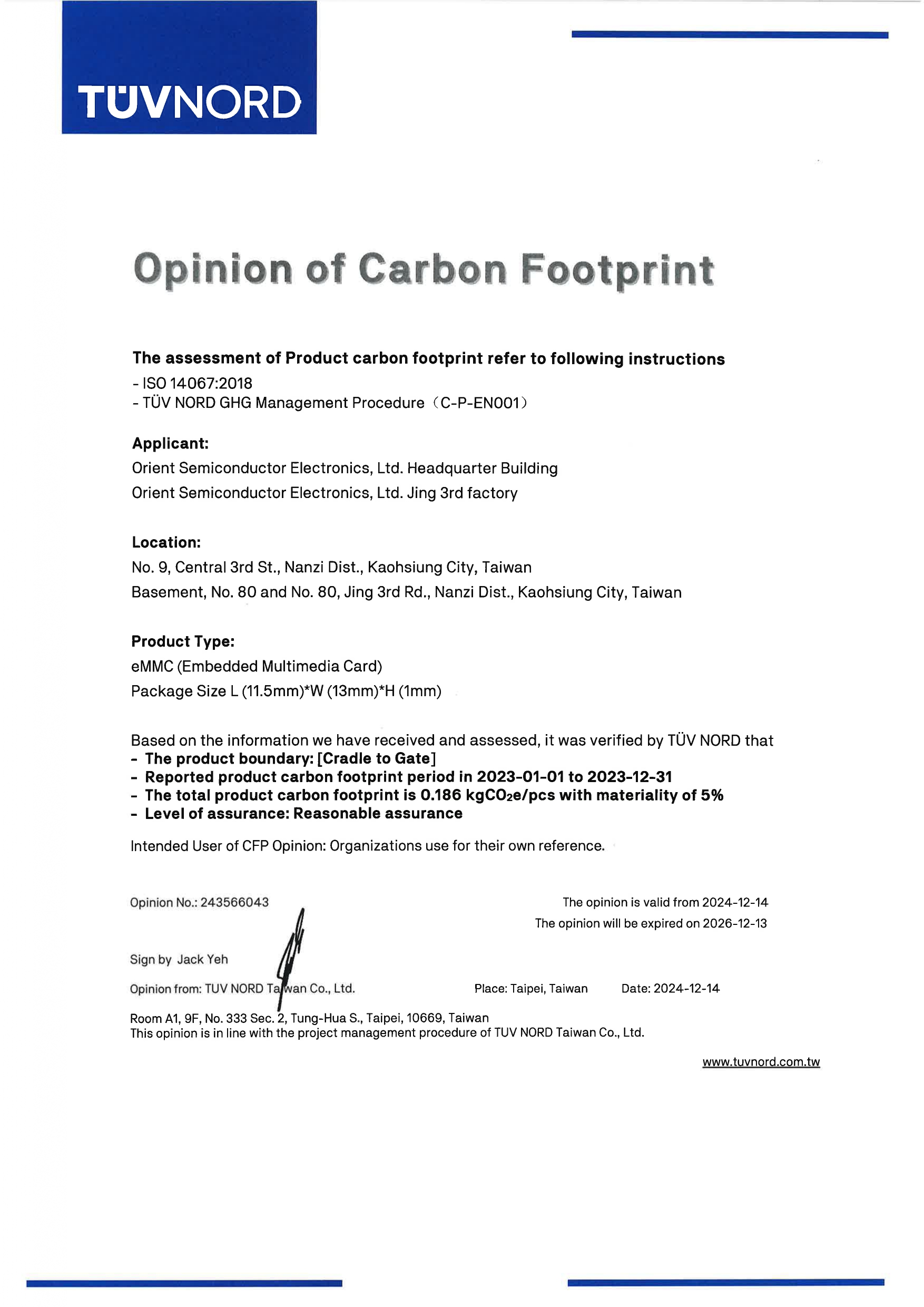

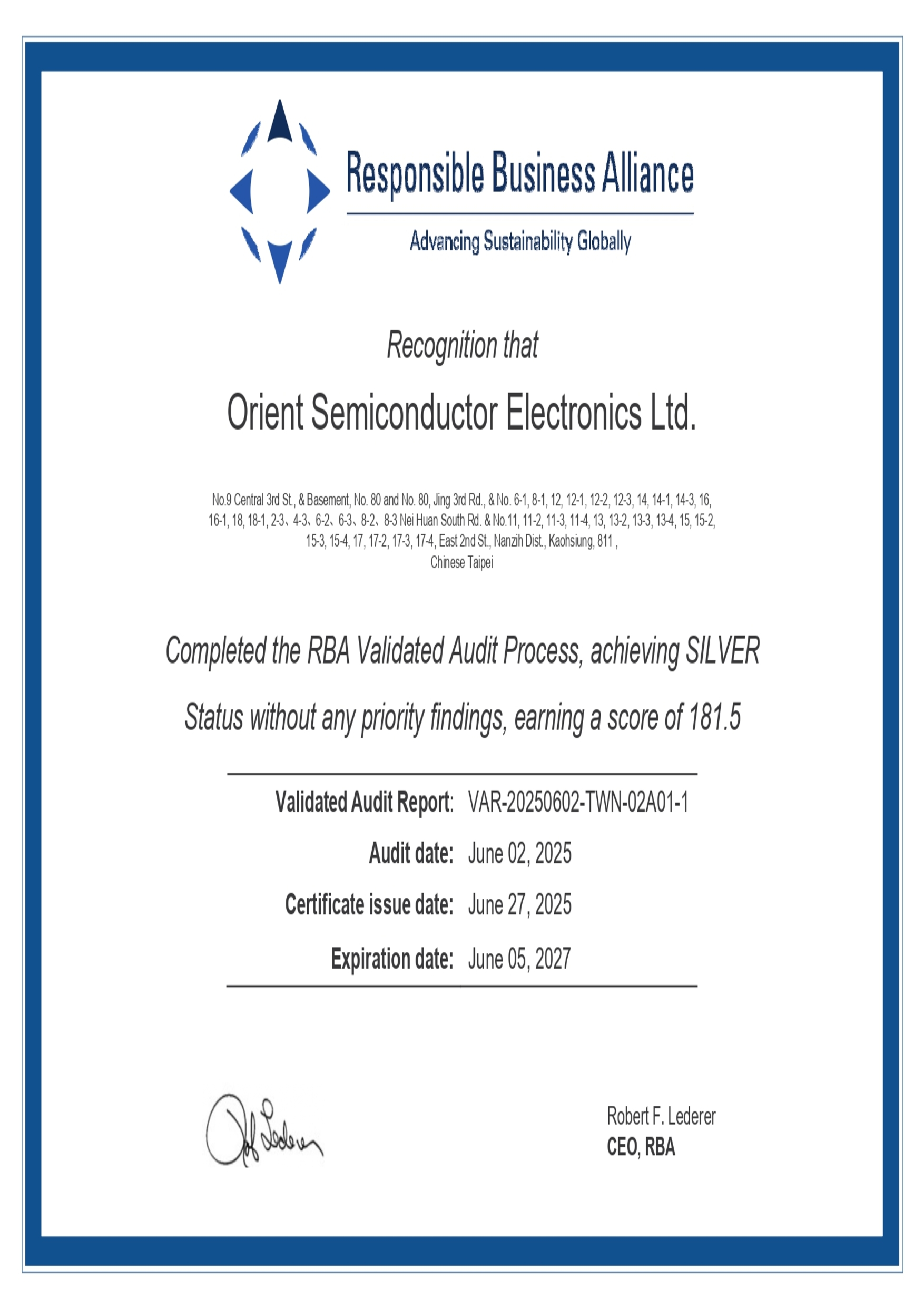

OSE Certificate

Our certifications attest our commitment to comply with international quality and environmental standards.

We work, however, to not only comply with these standards, but also continuously improve the effectiveness of our entire quality management system. Compliance with TAA(Trade Agreement Act).

IC SERVICES Certificate

EMS SERVICES Certificate

EHS SERVICES Certificate

*Note: The scope of certification and validity period are as specified in each certificate.

Information Security

Quality Management

Failure Analysis Lab

With the advanced equipment, OSE FA Lab has the capability to perform the failure analysis requests from customers and internal engineers for the continuous quality improvement.

FA request

FA requests from customers and internal engineers

Non-destructive Analysis

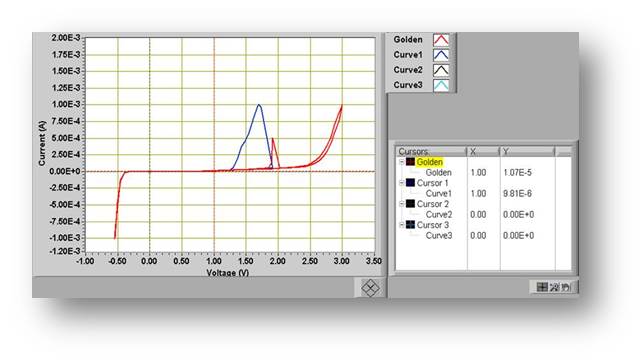

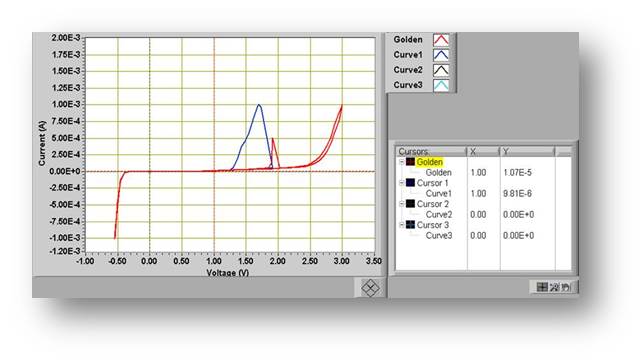

■Curve Tracer

■SAM

■X-Ray

■SEM&EDX

■Digital Microscope

■High/Low optical Microscope

Destructive Analysis

■Grinding/Polishing Machine

■Precison sectioning Saw

■Probe Station

■Laser Decap

■Ion Milling

FA Report

Non-destructive Analysis

Curve Tracer

KEITHLEY 2636B

Capability

1fA/1mV

Application

Curve tracer is a electronic test equipment used to analyze the characteristics of semiconductor devices.

X-ray

SEC X-eye SF-160

Capability

Real time observation

Application

X-ray is used for illustrate the internal structure through x-ray.

SAM (Scanning Acoustic Microscope)

Sonoscan D9650

Capability

Transducer frequency:

15MHz/30MHz/50MHz/100MHz

Application

SAM is used to examine, measure and photograph the IC structure with supersonic waves.

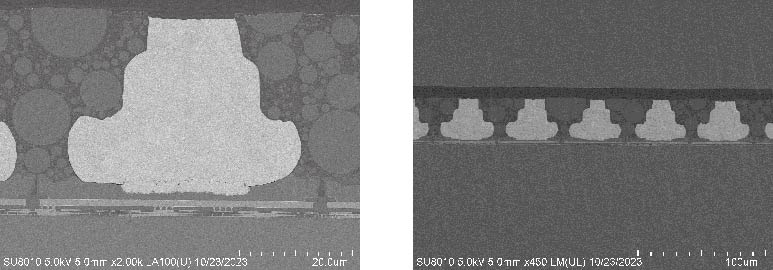

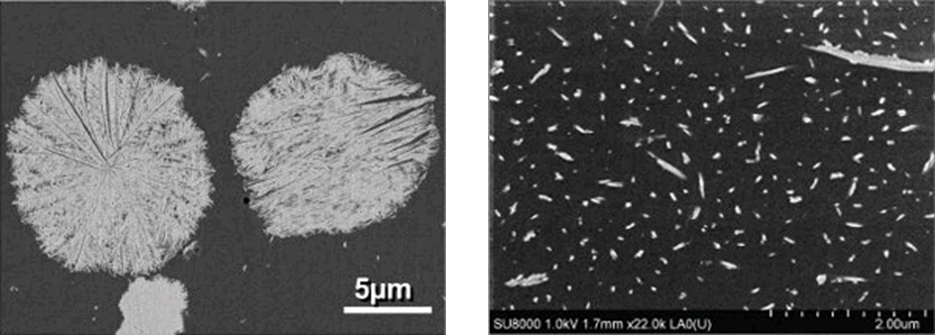

SEM (Scanning Electron Microscope) & EDS (Energy Dispersive Spectrograph)

Hitachi SU8010(SEM)

HORIBA X-max(EDS)

Capability

A/V.:0.5KV~30KV,

Magnification: 10X~100000X / Z:5~92

Detector area:50mm²

Application

SEM is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons.

EDS is an analytical technique used for the elemental analysis or chemical characterization of a sample.

Digital Microscope

KEYENCE VHX-7000 / EA300

Capability

Real Zoom Lens: 20X~4000X / Z: 1~92

Application

Digital microscope is an optical microscope that uses optics and a digital camera to magnify the sample with 3D contrast (DOF) to output to the monitor .

High/Low Power Optical Microscope

Nikon LV150

Capability

Eyepiece: 10X

Objective Lens:

2.5X/10X/20X/50X/100X

Application

High/Low Power Optical Microscope is a type of microscope to use visible light and a system of lenses to magnify the preliminary inspection of sample surface structure.

Destructive Analysis

Grinding/Polishing Machine

Struers Tegramin-20

Capability

Variable platen speed:

40~600 rpm

Application

The Grinding and Polishing machine is the tool used to grind/polish the sample near-by the suspected point for further investigations.

Precision Sectioning Saw

Allied 20-1000

Capability

Various Blade Type, Max Speed:4000 rpm

Application

Precision Sectioning Saw is the machine tools used for cutting the sample before grinding.

Laser Decap

Con Semi FAT cat II

Capability

I.R. Laser: 20 watt

Application

Laser Decap is the process of removing the protective cover of a microchip so that the contained die is revealed for visual inspection of the micro circuitry imprinted on the die.

Ion Milling

Hitachi IM4000

Capability

A/ V : 0 to 6 kV

Milling rate (max.) : (Materials Si)

For X-section milling: 300μm/hour

For Flat milling: 2~20μm/hour

Application

Ion milling machine thins the sample until it is transparent to electrons by firing ions at the surface from an angle and sputtering material from the surface.

Probe Station

MM 6000

Capability

4 Manipulator

Application

Probe station is used to physically acquire signals from the internal nodes of a semiconductor device.

Failure Analysis Equipment

| S/N | Equipment | Manufacturer | Model | Set | Capability |

| 1 | High/Low Power Optical Microscope | Nikon | LV 150 | 1 |

Eyepiece:10X, Objective Lens:2.5X/10X/20X/50X/100X |

| LV 150N | 1 | ||||

| 2 | Digital Microscope | KEYENCE | VHX-7000 / EA300 | 1 | Real Zoom Lens: 20~2000X / Z: 1~92 |

| VHX-7000 | 1 | Real Zoom Lens: 20~4000X | |||

| 3 | X-ray | SEC | X-eye SF-160 | 1 | Real time observation |

| YXLON | Y.CHEETAH | 1 | |||

| COUGAR | 2 | ||||

| Y.COUGAR SMT | 4 | ||||

| 4 | SAM (Scanning Acoustic Microscope) | SonoScan | D9650 | 1 | Transducer frequency: 15MHz/ 30MHz/50MHz/ 100MHz |

| 5 | Curve Tracer | KEITHLEY | 2636B | 2 | Resolution: 1fA/1mV |

| 6 | Laser Decap | Con Semi | FAT cat II | 1 | I.R. Laser: 20 watt |

| 7 | SEM (Scanning Electron Microscope) | Hitachi | S-3500N | 1 | A/V.:5KV~20KV, Magnification: 10X~100000X |

| SU8010 | 1 | A/V.:0.5KV~30KV, Magnification: 10X~100000X / Z:5~92 |

|||

| 8 | EDS (Energy Dispersive Spectrograph) | HORIBA | X-max | 1 | Detector area:50mm² |

| 9 | Probe Station | MM | 6000 | 1 | 4 Manipulator |

| 10 | Cross Section Machine | Struers | Tegramin-20 | 1 | Variable platen speed: 40~600 rpm |

| 11 | Ion Milling | Hitachi | IM4000 | 1 |

A/ V : 0 to 6 kV Milling rate (max.) : (Materials Si) For X-section milling: 300μm/hour For Flat milling: 2~20μm/hour |

| 12 | Precision Sectioning Saw | Allied | 20-1000 | 1 | Various Blade Type, Max Speend:4000 rpm |

OSE establishes quality management system according to IATF 16949 and ISO 9001 and develops customer-oriented processes. We continually assess and monitor effectiveness and efficiency and use many kinds of quality management tools to satisfy out customers and expectation and enhance advantage competition.

.png)

.png)

1_page-0001.jpg)

1_page-0001.jpg)